Cyclops is an Integrated Risk Management (IRM) platform, created to manage the risks related to the asset obsolescence and lifecycle in the Industrial Plant.

One of the most important concept considered in the platform is the “Observability“. Cyclops is able to give a support to the management of the processes in order to have the full control on the production, monitoring the risks related to the assets involved in it.

Cyclops considers the concept of “Observability“ one of the most relevant one to be managed in an industrial process.

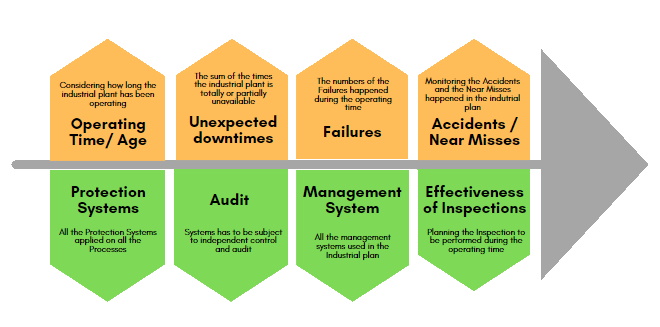

The ageing of the industrial asset is a extremely crucial aspect because it could grow esponentially the risks during the production.

A lot of different assets are involved in an industrial process, located in a single Industrial Plan or in different ones, and sometimes managed by different companies in a single supply chain. In general, this could make the data recovery process complicated.

Asset Operating Time and Age

Stop on the Production Line

Audit and Effectiveness of Inspections

Protection and Management Systems

Indipendent relevations on the assets and monitoring the failure – and “near misses” too – could be really important, but one of the crucial element involved in it is the effectiveness of the inspections – so how the deterioration could be misured – and the planning of the inspections.

Cyclops aimed data-driven enterprise that wants to manage components and subsystems obsolescence, in order to optimize the production processes and reduce the risks related to the asset lifecycle.

The Mechanisms of Deterioration are linked to other sub-factors: severity of the consequences, ability to detect the main damage mechanisms (by inspection) and propagation speed of the mechanism.

This could be shown as a three dimentional cube where the sub-factors are the directions and for each one is it possible to give a value from 1 to 4.

Detectability: ease of detecting the phenomenon and measuring its effects

Velocity: extent of the propagation of the phenomenon over time

Consequences: entity of the loss of containment caused and dangerousness of the substance

The whole risk detection and management process takes into consideration the Integrity of the equipment as a fundamental factor. The goal of the Risk management is to minimize the impact on the plant’s safety process.

Three factors are considered on the Risk detection:

Reliability, the reliability of the plant as a whole, considering it as a set of various pieces of equipment combined in a more or less complex way.

Availability, the possibility of using all the equipment that make up the system to the best of one’s possibilities

Safety, the ability of the plant to be used in production processes without causing damage to the production itself, to the workers who will fill it or to the environment, with pollution.

Considering the three sub-factors in the degradation and the three factors in the Risk detection, is it clear that speed in feedback are crucial. The speed and the clear view on “what to do” in order to ensuring the correct functioning of the facilities.

Cyclops is focused on providing a tool for Resilience

.

The Speed of Intervention is crucial and the representation model that has also been generated at an academic level is the non-linear one.

Complex systems are dynamic and must be able to adjust their performance according to the conditions that arise.

Complex systems must be dynamically stable: Stability fluctuations must always be under control.

The essence of Resilience is the ability of the system to maintain a dynamically stable state.

The management of risk related to the life cycle of assets has a high impact on the business.

A product / asset, which is end-of-life introduces a multiples issues to be managed:

end of support – serious failure of assets cannot be restored, with degradation and/or interruption of service;

Security vulnerabilities – lack of support for resolving new security issues (risks to service delivery, data loss, and corporate reputation);

Investment planning and prioritization – Allocating the budget needs for both purchasing and replacement of the asset.

Lifecycle & Maintenance

Product and support lifecycle management. Definition of priorities in budget definition for the evolution of the infrastructure.

Digital Risk Management

Assessment and control of risk related to asset obsolescence. Management of both Remediation and Risk Mitigation process.

Financial Planning & Management

Investment planning and tracking of the purchasing process. Supplier qualification and performance process (Vendor Rating).

Operations & Project Planning

Project Management and development activities; priorities definition and activities correlation depends on risk remediation process.